|

How to select the correct spring (Please Read) First of all it is very important to have the correct spring for your door, if the spring is not matched correctly to the door, it will not work properly and can be dangerous or damage your operator. Make sure that you measure the spring correctly and if you have questions, please call or message us before ordering. Step 1 is to measure the wire diameter. To do this you will need to measure 10 coils then compare that measurement to the chart below to see the wire size. Double check by measuring 20 coils and comparing to the 10 coil measurement. If the two measurements do not match, try measuring in a different area of the spring and also make sure that the spring is not stretched. Do not measure on the ends where the cones are; the cones stretch the ends where they are installed.

| Torsion Spring Wire Chart | | 10 Coil Measurement in inches | 20 Coil Measurement in inches | Wire Size | | 1 1/2" | 3" | .148 | | 1 9/16" | 3 1/8" | .156 | | 1 5/8" | 3 1/4" | .162 | | 1 3/4" | 3 1/2" | .177 | | 1 7/8" | 3 3/4" | .187 | | 1 15/16" | 3 7/8" | .192 | | 2" | 4" | .200 | | 2 1/16" | 4 1/8" | .207 | | 2 3/16" | 4 3/8" | .218 | | 2 1/4" | 4 1/2" | .225 | | 2 5/16" | 4 5/8" | .234 |

|

|

| | 2 7/16" | 4 7/8" | .243 | | 2 1/2" | 5" | .250 | | 2 5/8" | 5 1/4" | .262 | | 2 3/4" | 5 1/2" | .273 | | 2 13/16" | 5 5/8" | .283 | | 2 7/8" | 5 3/4" | .289 | | 2 15/16" | 5 7/8" | .295 |

|

Step 2 is to determine the spring inside diameter, if the spring is broken you can simply use a ruler to measure the inside of the broken end, if the spring is still in one piece you can measure the outside and deduct the wire size X 2. You also may be able to find stampings on the cones which will help determine the ID, ( P200 or P2000 for 2” and P175 for 1 ¾”) The most common sizes in residential springs are 1 3/4" and 2" ( Raynor doors use 2 ¼” ID )*Note: the .237 wire size has been discontinued, if you have that wire size, message or call us with the size of the spring for a replacement size.

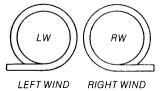

Step 3 is to measure the length of the spring, Measure the spring only, not including the winding and stationary cone. If the spring is broken measure each piece and add the two measurements together to get the total length. If the spring is still in one piece and wound, it will be longer by 2-3” then when it is relaxed.. the proper way to measure is to unwind the spring to measure the correct length, Step 4 is only important if ordering a single spring, determine the wind direction of the spring, ( right hand wind ( RW) or left hand wind (LW). Below is an example of the different spring winds. This is probably the most confusing part of the spring ordering process, as The RW is normally on the Left side and the LW is normally on the Right side. Be sure to check the wind direction and not make assumptions. If you look at the end of the spring and compare to the picture below, you will be able to determine the correct wind direction.  Need help installing or ordering the springs? We provide free support on any products purchased from us. For ordering help, call (814) 573-2563. For installation help or other technical questions, call (814) 282-9242

Read our return policy here

|